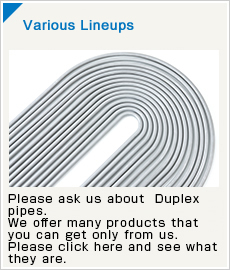

BA Coil

It is typical to plumb and weld with specified length pipes at semiconductor and LCD plants

Improper welding, metal fumes, and slags are the main causes to decrease the liquid purity and corrosion resistance. It also causes to occur particles, tiny dust. Consequently, it takes more time to manage welding rules and improper welding check.

For instance, if you used 4m pipes in 200m construction, you have to weld 49 times at least. By using seamless BA coil, you do not need to weld anymore.

Seamless pipes BA stock list

| Diameter (Inch) |

SIZE Outer diameter(mm) * thickness(mm) |

Length |

BA | ||

|---|---|---|---|---|---|

| 304 | 316 | 316L | |||

| 3.0×0.5 | 30M | ○ | ○ | - | |

| 3.0×1.0 | ” | ○ | ○ | - | |

| 1/8 | 3.18×0.5 | ” | ○ | ○ | - |

| ” | 3.18×0.72 | ” | ○ | ○ | ○ |

| 4.0×0.5 | ” | ○ | ○ | - | |

| 6.0×1.0 | ” | ○ | ○ | ○ | |

| 1/4 | 6.35×1.0 | ” | ○ | ○ | ○ |

| 8.0×1.0 | ” | ○ | ○ | ○ | |

| 3/8 | 9.53×1.0 | ” | ○ | ○ | ○ |

| 10.0×1.0 | ” | ○ | ○ | ○ | |

| 12.0×1.0 | ” | ○ | ○ | - | |

| 1/2 | 12.7×1.0 | ” | ○ | ○ | - |

*We make an estimation for the other sizes.

*We are ready to do quick delivery and special order.

Characteristics

a) Sustaining high cleanliness

Because a number of welding point is reduced, particles decrease consequently.

Also it prevents contaminants to get into the line so that the process of construction can be revised.

b) Less welding

Thanks to its few welding points the risks such as welding mistakes and corrosion resistance degradation.

c) Shortening construction period

As well as the advantages above it reduces the time to construct, for it is using the portable coil stretching machine.

d) Safety

BA coil is a seamless tube. There is no need to worry about a leak because of the total pressure inspection.

e) Quality

Although it differs more or less in quality by the vendor, generally the smoothness of BA coil tubes is made as Ry≦4.5μm. Please contact us, when needed, about size tolerance and inner smoothness.

We remove particles, contaminants, liquid by careful cleaning with hot pure water/ultra sonic wave and by baking in order to meet the demand on high cleanliness. After that these items are delivered to you in the best possible quality by sealing with Cap Union.

Manufacturing process

Seamless stainless steel pipes is made by cold-drawing and then cut in ordered size.

Heating

We choose a bright heat treatment method (Vacuum chamber) as solution treatment method at 1010℃ heat.

Finishing

Bright heat treatment method (Vacuum chamber finishing)

Manufacturing process