Tons of products arrive and are delivered in the stock yard next to the head office every week. Work starts at once at 8am. There is a line of trucks by the stock yard. It seems like the warehouse is swallowing trucks, and our staffs are letting them in and out by skillfully manipulating cranes.

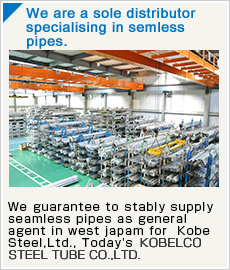

We are a general agent, first distributor, of Kobelco Steel Tube in west Japan area, and sells stainless steel pipes. Thanks to a stable supply from the vendors, we are able to organize to meet any customers' needs.

Our prime products are pipes for plumbing, seamless pipes for machine structure and heat exchanger, and fittings. Especially a number of stock of BA(Bright Annealing) pipes and EP (Electro Polishing) pipes is one of our key strengths.

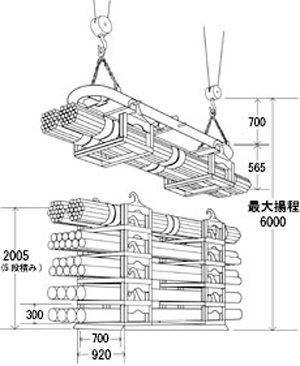

Hence, We have a wide range of industries as our customer such as ship makers, car makers, chemical plants, power suppliers, nuclear power plants, paper manufacturers and semiconductor makers, covering mainly west Japan, Kanto area, and asian nations. The support area is still expanding. Our Toku-Toku racking system allows warehouse workers to reduce time to put things in and collect them.

"Toku-Toku racking system" – Multi-tiered racking system![]()

![]()

This racking system is a storage method which makes it possible to fill the upper dead spaces of your warehouses.

The point is a maximum lift height of the roof crane. For example, if the maximum height was 6m, 11 racks can be loaded with a rack of 300mm inside dimension hypothetically. In reality, because there needs some space to exchange racks, it would be 10 racks loaded.

Due to that the smallest cradle rack can contain 4t, 1 row can store 40t.

![]()

![]()

We have been merchandised seamless pipes since foundation. Currently, Our headquarters and main warehouse are located in Minato-ku, Osaka City, with a Tokyo office in Minato-ku, Tokyo. In 2014, headquarters and warehousing was relocated to a new location.

For more than 50 years of experiences to sell seamless pipes, We try hardly to meet your demand as a specialist.

In order to use this system, you need the given ID and password by us.

Click HERE for more information.

Cutting facility

To deliver your order "more quickly, more safely, more accurately," We use the CNC high accuracy quick cutter, DYNASAW, a series of HFA400 cutters which contains NC programming function, PCSAW330 which is a pulse cutting band sawing machine, Hitachi rotary bandsaw machine. We cut as you order in size.

Deburring work

We carefully deburr and get rid of tiny dust inside by air blowing to every single product. We are using specific deburring machine in manual bases by our experts so that it can keeps high quality, safety and beauty in appearance.

About PMI (Positive Material Identification )![]()

![]()

We installed Niton XL2, PMI system fin 2013. It is capable to identify immediately more than 415 of steel type including a tiny amount of the elements. Now we can quickly check if the combination of the order and the material was ideal or not. It is quite handy to use, for it is about 1.7kg, so that we can check a specific point easily.

Due to that seamless pipes and its processed pipes are installed in plumbing work and machines, they are used under specific conditions. If it contained alien substances, it may cause serious problems. We carefully inspect product at receiving and shipping stage so that we can deliver quality items in order customers to be assured. We continue to gain capabilities to prevent alien substances and to increase quality.

![]()

![]()

We would like you to tell us that you need your MTRs when ordering. Nowadays, they will immediately be issued on receipt of your orders by using an online system with our manufacturers.

If you have problems with how to read your MTRs or you want more information on them, please refer to page 102 of our PDF catalogue.

PDF Catalogue![]()

![]()

![]()

![]()

Please contact me if you have a package preference or you would like to export.

Because thin pipes especially requires careful delivery method to avoid any damages on them, We are packaging with wood splints, cardboard tubes, plastic sheets, and Apton (hard plastic sheets). For pipes for semiconductor plants, wood boxes, sacks, and protection cap are used with it in order to protect.

We are cooperating with dozens of logistics companies. It allows us to make decision rapidly and accurately on the way of delivery via land, sea, or air route.

Managing this logistic network is one of our key strengths and characteristics. We, for instance, change the way to deliver item by item. On the one hand, We use a parcel delivery service for small-sized items, on the other hand, We use a regular delivery for 4m/5.5m long pipes, or use a charter delivery for heavy items.

We have made every effort to make better shipping networks to always meet your satisfaction.

We basically ship your products on the same day as when you order. ![]()

![]()

For orders under 30 kg and not longer than 'size 170 cm', we can ask SAGAWA EXPRESS CO.,LTD, YAMATO TRANSPORT CO., LTD or Yu-Pack to ship them. For more information, please contact us.

| Area | arrived in | by us or shipping company |

|---|---|---|

| Hokkaidou | 2-4 days | by shipping company |

| Tohoku | 2-3 days | by shipping company |

| Kantou | 1-3 days | by shipping company |

| Hokuriku | 1-2 days | by shipping company |

| Toukai | 1-2 days | by shipping company |

| Kinki | 0-1 day | by us or shipping company |

| Chugoku | 1-3 days | by shipping company |

| Shikoku | 1-2 days | by shipping company |

| Kyushu | 1-3 days | by shipping company |

![]()

![]()