Others

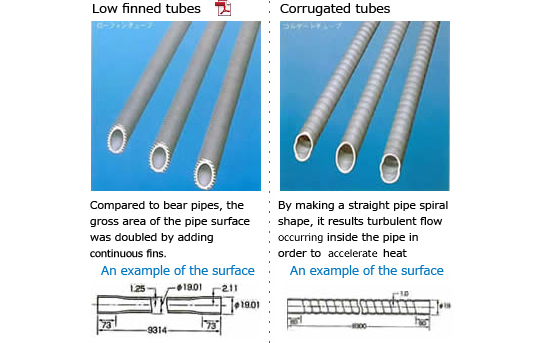

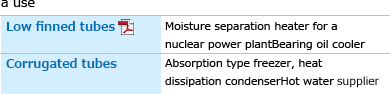

Compare to regular pipes, we make it possible that they are finned to increase outside surface, corrugated to make undulations on the surface.

We established the processing method especially for the stainless steel materials which are hard to process.

Characteristics

1. By deforming a shape of pipe surface like the figure below, it results high overall heat transfer coefficient for heat transmitter.

2. Compare to the other heat exchangers, it decreased a total length of pipes. If it was under the best condition,

it is possible to make the pipe length approximately 1/3 to 1/2, and to make the size of whole system 1/2.

3. By matching liquid type and suitable stainless steel and alloy, it is possible to make.

4. For it is monolithic molding, it has high impact resistance and vibration resistance.

Other low finned tubes

Characteristics

1. Finesse are helically put on the pipe surface in the same pitch and carefully sized by following strict standard.

2. It is uniformly produced with the special mechanism allowing it to keep quality.

3. It eases the speed of gas pollution because of its less weld beads. It is quite easy to clean.

4. As the image of cross sections below, the depth of tube penetration is quite shallow. There is almost no need to consider an affection to the material.

Moreover, it has enough toughness by following the global standard of pulse resistant welding finned tubes, minimum a,

17.6kgf / m㎡ of penetration strength.

5. We can make the best product for you to combine possible fin and tube materials for specific purposes.

Characteristics

1. Thermal conductivity increases 10% to 15% because turbulent flow happens to gas by serrate inside.

2. You can make the whole system smaller with it. The necessary area of heat transfer decreases due to its high thermal conductivity.

As a result, a number of finned tubes can be reduced.

3. For clean gas, the effectiveness of serrate is maximized. For these reasons, you can achieve cost down.

A gauge pipe is used as a needle (medical purpose and food).

| Sign (G) | Outer diameter mm | Thickness mm | Inner diameter mm | Length mm | Difference | Specified lengths | |

|---|---|---|---|---|---|---|---|

| Outer diameter | Inner diameter | ||||||

| 30G | 0.31 | 0.09 | 0.13 | 1000 | ±0.01 | ±0.02 | ○ |

| 29G | 0.33 | 0.09 | 0.15 | 1000 | ±0.01 | ±0.02 | ○ |

| 28G | 0.35 | 0.09 | 0.17 | 1000 | ±0.01 | ±0.02 | ○ |

| 27G | 0.41 | 0.11 | 0.19 | 1000 | ±0.01 | ±0.02 | ○ |

| 26G | 0.45 | 0.11 | 0.23 | 1000 | ±0.01 | ±0.02 | ○ |

| 25G | 0.51 | 0.125 | 0.26 | 1000 | ±0.01 | ±0.02 | ○ |

| 24G | 0.55 | 0.125 | 0.3 | 1000 | ±0.01 | ±0.02 | ○ |

| 23G | 0.63 | 0.15 | 0.33 | 1000 | ±0.01 | +0.04 -0.01 |

○ |

| 22G | 0.71 | 0.15 | 0.41 | 1000 | ±0.02 | +0.04 -0.02 |

○ |

| 21G | 0.81 | 0.15 | 0.51 | 1000 | ±0.02 | +0.04 -0.02 |

○ |

| 20G | 0.88 | 0.15 | 0.58 | 1000 | ±0.02 | +0.04 -0.02 |

○ |

| 19G | 1.06 | 0.18 | 0.7 | 1000 | ±0.02 | +0.04 -0.02 |

○ |

| 18G | 1.26 | 0.18 | 0.9 | 1000 | ±0.02 | +0.04 -0.02 |

○ |

| 17G | 1.48 | 0.18 | 1.12 | 1000 | ±0.02 | +0.04 -0.02 |

○ |

| 16G | 1.61 | 0.18 | 1.25 | 1000 | ±0.02 | +0.04 -0.02 |

○ |

| 15G | 1.81 | 0.18 | 1.45 | 1000 | ±0.03 | +0.04 -0.02 |

○ |

| 14G | 2.11 | 0.21 | 1.69 | 1000 | ±0.03 | ±0.08 | ○ |

| 13G | 2.41 | 0.21 | 1.99 | 1000 | ±0.03 | ±0.08 | ○ |

| 12G | 2.76 | 0.18 | 2.4 | 1000 | ±0.03 | ±0.08 | ○ |

| 11G | 3.06 | 0.21 | 2.64 | 1000 | ±0.03 | ±0.08 | ○ |

| 10G | 3.4 | 0.28 | 2.84 | 1000 | ±0.03 | ±0.08 | ○ |

| 9G | 3.75 | 0.28 | 3.19 | 1000 | ±0.03 | ±0.08 | ○ |

| 8G | 4.2 | 0.28 | 3.64 | 1000 | ±0.03 | ±0.08 | ○ |

| 7G | 4.57 | 0.28 | 4.01 | 1000 | ±0.03 | ±0.08 | ○ |